Biosolids

PFAS in Biosolids

What are Biosolids?

Biosolids are the remaining organic materials following the treatment of sewage at wastewater treatment plants (WWTPs). WWTPs receive influent wastewater from domestic sewage, industrial discharges, storm water and landfill leachate. These materials are rich in nutrients including nitrogen, phosphorous and potassium and can be beneficially reused as soil amendments after treatment to kill pathogens and reduce contaminants. Biosolids can play an important role in sustainable agriculture through building organic soil matter, improving soil health, and increasing carbon sequestration while offering an alternative to chemical-based fertilizers. Biosolids can come in various forms including liquid, dewatered, slurry, cake, composted materials, or dried pellets.

There are two main types of biosolids produced by WWTPs in Michigan, Class A Exceptional Quality or Class B. “Class A Exceptional Quality” biosolids are biosolids that meet both the Class A and Exceptional Quality (EQ) standards for pathogen reduction, metal limits and vector attraction standards. Vectors, including flies, birds, rodents, mosquitos, etc., are often hosts of various pathogens, and they can transmit diseases to humans. Vector attraction reduction is a process that makes biosolid products less attractive to these vectors or hosts and ultimately reduces the potential for transmitting diseases. Class B biosolids are treated to the point where they are deemed safe for use as soil amendments or fertilizers. These biosolids have site restrictions for soil conditions, season of application, timeframe for incorporation into the soil, public access to land, and setback distances to protect ground and surface water. Class A EQ and Class B biosolids can be applied to agricultural land, forests, public contact sites and reclamation sites, while only Class A EQ biosolids can be used for lawns, home gardens and bagged material for commercial sale.

People will often use the term “biosolids” or “sewage sludge” interchangeably, but there is an important difference. Sewage sludge refers to the solids that settle out during the wastewater treatment process. These solids are not yet treated and may contain pathogens or contaminants from various influent sources. Biosolids are produced by treating sewage sludge to meet specific standards set at the federal level by the Environmental Protection Agency (EPA) and at the state level by the Department of Environment, Great Lakes and Energy (EGLE). These biosolid products that have received treatment to reduce certain contaminants and pathogens are the products used for land application, not raw sewage sludge.

Another type of product often confused with sewage sludge or biosolids is called “septage”. Septage is the liquid or solid material that is removed from septic tanks, cesspools, portable toilets, Type III marine sanitation devices or other storage/treatment works that only receive domestic septage. This type of waste only receives domestic inputs rather than getting waste from industrial sources. This means that any potential contamination from pathogens, chemicals and/or pharmaceuticals would come from whatever household or personal care products were used.

For more information, click here to see:

Biosolid Management in Michigan

PFAS Management

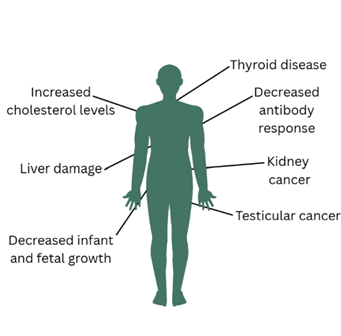

One concern with land application of biosolids is the potential for these products to contain contaminants that were not removed by treatments including per- and polyfluoroalkyl substances otherwise known as PFAS. These compounds are also known as “forever chemicals” because their bonds are incredibly strong and resist degradation by natural processes. This lack of degradation, combined with their affinity for soils and living tissues causes PFAS to bioaccumulate in the environment, water, soil, animals, and humans. High levels of exposure to these compounds have been associated with a range of health conditions such as decreased immune function, liver damage, thyroid disease, reproductive and developmental effects, decreased response to vaccination, liver, kidney and testicular cancers and more. It has been estimated that 98% of the U.S. population has detectable levels of PFAS in their blood. These compounds have also been found all over the world, including remote areas like the Arctic.

Figure 1 Some of the health effects associated with long term cumulative PFAS exposure. Research is still ongoing in this area, so this list may not include all associated health conditions.

In Michigan, biosolids are regulated by EGLE’s Water Resources Division (WRD). In early 2018, the WRD developed the Industrial Pretreatment Program Initiative Study to examine 95 municipal WWTPs to try and identify the main sources of PFAS entering the wastewater collection systems. After identification, their aim was to systematically reduce or eliminate sources of PFAS, specifically perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS), from entering the WWTPs. PFOA and PFOS are two of the most commonly studied PFAS and are known to be the most toxic in terms of their widespread usage and bioaccumulative potential in humans. During this study, PFOA was not detected above the state water quality values in any WWTP effluent, so PFOS became the main driver for regulation. The Industrial Pretreatment Program Initiative Study identified 6 WWTPs with industrially impacted biosolids and temporarily restricted their land application programs until these elevated levels of PFOS were eliminated. In this study, WWTPs were determined to be “industrially impacted” if the residuals had PFOS concentrations above 150 µg/kg (ppb).

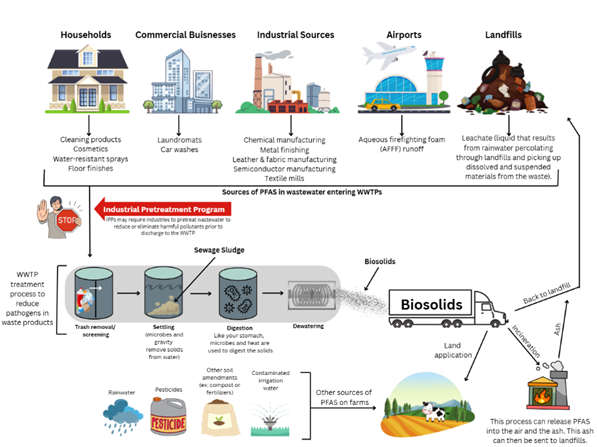

Figure 2 Pathway for PFAS contamination to move into biosolids from airports, landfills, residential, commercial and industrial sources.

Figure 3 PFAS cycle between industry, landfills, surface water, groundwater, farmland, and wastewater treatment plants. The red boxes indicate where the Industrial Pretreatment Program aims to reduce PFAS in influent wastewater and landfill leachate. The white boxes coming from industrial sources and WWTPs show the discharge limits in place for wastewater effluent into streams. Graphic from: https://www.michigan.gov/egle/about/organization/water-resources/industrial-pretreatment/pfas-initiative

Following the initial Industrial Pretreatment Program Study, the WRD conducted a study in the fall of 2018 monitoring the influent, effluent and residuals of 42 WWTPs. Influent is the untreated water flowing into the WWTP for processing while effluent is the water that flows out of the WWTP back into the environment. Residuals refer to the various solid, semi-solid, or liquid byproducts from WWTPs, including biosolids and sewage sludge. This study also monitored 29 land application sites to better understand the impact that biosolid applications have on the environment. The results of this study found PFAS in 134/134 water samples (influent and effluent) and 69/71 solids samples (sludge or biosolids) collected. The water samples contained more of the shorter chain PFAS while the solid samples detected higher concentrations of long chain PFAS (see figure below for more on PFAS chain length). Another interesting finding showed that for 36/42 effluents, PFOA concentrations were higher than the influent levels. This finding suggested a potential transformation of PFAS precursors into other PFAS compounds like PFOA and/or that there was recirculation of PFAS through various treatment streams. PFOS was detected in 43/45 final treated solid samples and had an average concentration of 184 ppb and a median concentration of 13 ppb. Seven of these solid samples had levels above 150 ppb, which is the level EGLE deemed “industrially impacted” at the time of this study. When these 7 samples were removed from the average calculation, the recalculated average amongst solid samples dropped from 184 ppb to 18 ppb. For more information on the findings from this study, click here to review the full report.

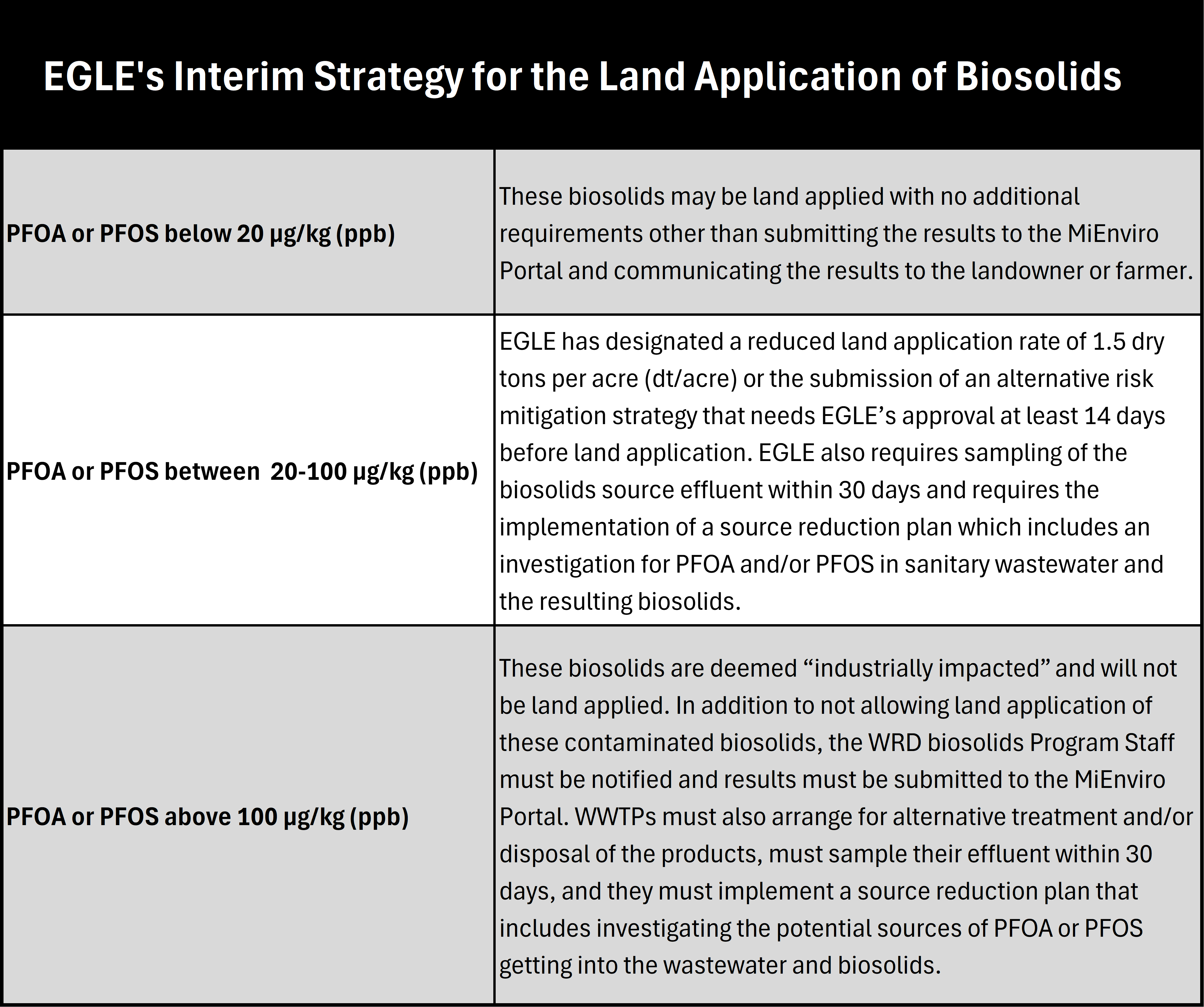

Along with these studies and source reduction strategies, EGLE’s WRD is also monitoring biosolids used for land application for two of the most toxic and bioaccumulative PFAS: PFOS and PFOA. In this interim strategy, there is a three-tier system that determines the land application rate and regulations for biosolids used for land application.

Table 1 Michigan’s Interim Strategy for the Land Application of Biosolids.

This interim strategy for the land application of biosolids containing PFAS took effect as of January 1, 2024. All facilities that apply Class A or Class B biosolids are required to collect one representative sample of the biosolid product per calendar year before land application takes place. Some biosolids can also be designated as “Exceptional Quality” (EQ), which means that the testing of the biosolid products is required quarterly rather than annually. These exceptional quality biosolids also must be at or below a combined PFOA/PFOS concentration of 20 ppb. For more information on biosolids management in the State of Michigan, click here.

Other contaminants

EGLE is currently monitoring biosolids for arsenic, cadmium, copper, lead, mercury, molybdenum, nickel, selenium, zinc and 28 different PFAS analytes. For more information about the regulation of non-commercial fertilizers like Class A EQ Biosolids, Class B Biosolids, septage, manure and industrial by-products visit the Michigan Water environment Association’s page.

For land applications to take place, they must be applied at an agronomic rate that cannot exceed the recommended concentrations of nitrogen, phosphorous, and potassium (NPK) in the soil. The agronomic rate is also dependent on the intended crops being grown. These sites must have soil testing done every two years to provide accurate recommendations for application rates. Biosolids applied at the agronomic rate minimize the risk of excessive nutrients entering the soil and potential runoff.

Advantages of Biosolid Land Application

Wastewater treatment plants are faced with three possible choices for what to do with waste products they receive; they can either be sent to landfills, incinerated or used for land application as a fertilizer source. Both landfilling and incineration are costly options that also have potential for environmental contamination. When landfilling wastewater solids, there is potential for contaminants to leach from the landfill into the surrounding soil and groundwater. If landfilling were the only way to dispose of these products, landfill capacity would be greatly impacted due to the high quantity of solid waste materials being received. Many landfills also require biosolids to be dewatered to an extent that many facilities do not have the capacity to achieve. When these solid waste products are incinerated, some contaminants could pollute the air stream and the resulting ash products would enter landfills and possibly lead to further contamination via landfill leachate. Incineration may not destroy all contaminants, such as PFAS, and the impact of incinerating these chemicals is largely unknown and needs more research. There are also very few incinerators in Michigan that accept biosolids. Given that these two methods solely intend to dispose of solid waste products, biosolid land application provides a beneficial reuse method that can improve plant growth and soil fertility due to the high concentrations of essential nutrients in biosolids. Since 2015, the Michigan Biosolids Program has kept over 1.3 million dry tons of biosolids out of landfills (for reference, this is the equivalent of 1.25 Mackinac Bridges).

Biosolids are a source of organic matter and can be used in place of conventional, mineral, or chemical fertilizers. They contain important nutrients such as nitrogen, potassium and phosphorus, along with micronutrients like copper, iron, zinc, and molybdenum. In addition, biosolid usage helps to build soil and maintain soil carbon while reducing CO2 entering the atmosphere. These increases in soil organic matter provided by biosolid land application can also lead to greater aeration, water infiltration, erosion resistance, and greater microbial diversity. High levels of organic matter in soil have also been shown to increase binding of PFAS to the soil, leading to lower levels of PFAS moving into groundwater or plants grown in the soil. According to the Energy Information Administration’s cost and efficient estimates for Michigan, this reuse of biosolids has also led to greenhouse gas reductions equivalent to a $100 million solar facility.

A concern that arises from amending soil with fertilizers is nutrient runoff. This runoff can lead to algal blooms, fish kills, and ecosystem disruptions. Biosolids tend to have a lower risk of nutrient runoff due to the nutrients being bound to the organic materials found in biosolids. These nutrients and the organic matter they are bound to are also not easily dissolved in water. These properties show that biosolids can be a safer alternative to commercial fertilizer applications when it comes to nutrient runoff concerns.

Overall, with good management and regulations in place, biosolids can be a great alternative to commercial fertilizers. Not only do biosolids add essential nutrients into the soil, but they are a very cost-effective option for farmers. Land application of biosolids can also reduce the environmental harm that would result from landfilling or incinerating all solid waste products from WWTPs. Biosolid applications can also improve soil health, help to increase crop yield, increase microbial activity and sequester carbon from the atmosphere to help combat climate change.

Disadvantages of Biosolid Use

Although there are many advantages to the land application of biosolids, there are some drawbacks to be aware of before applying them to your land including odor, contaminants, neighbor relations, etc. Despite going through several treatment processes, biosolids can still carry some levels of synthetic chemicals, microplastics, metals and pharmaceuticals. Regarding PFAS specifically, EGLE is regulating PFOA and PFOS levels in biosolids, however, there are over 12,000 different types of PFAS that exist and may potentially be present in biosolids. Although they are only regulating two PFAS compounds, they are two of the most toxic, persistent and bioaccumulative types of PFAS.

Another potential concern for biosolids usage would be the frequency of testing conducted for PFAS in biosolids. “Excellent Quality” (EQ) biosolids are tested 4x/year whereas all other biosolids used for land application are monitored 1 time per year. Although this monitoring is valuable to track PFAS levels in biosolids, the concentrations may not be consistent on an annual or quarterly basis.

Another potential drawback of biosolid applications would be issues caused by the application odor. Biosolids can smell unpleasant and may result in issues with neighbors if the application took place near a residential area. Microbial action breaking down biosolids in the soil may also create odors as well. WWTPs are required to notify the landowner receiving biosolids and local health departments prior to land application, but they are not required to notify landowners neighboring the property.

Should You Accept Biosolids for Land Application?

While this is a tough question to answer, it is important to educate yourself on where biosolids come from and how they are regulated. It is also important to think about the risks for your specific farm. For example, research shows that PFAS tends to accumulate more in grasses and leafy greens than root vegetables and grains. This finding highlights the importance of understanding the risks of biosolids application for farmers whose animals are grazing on crops with a higher potential to accumulate PFAS. Fields used to grow grains may be a more suitable candidate for the land application of biosolids when it comes to potential PFAS exposure since grains have been found to accumulate less PFAS than other crops.

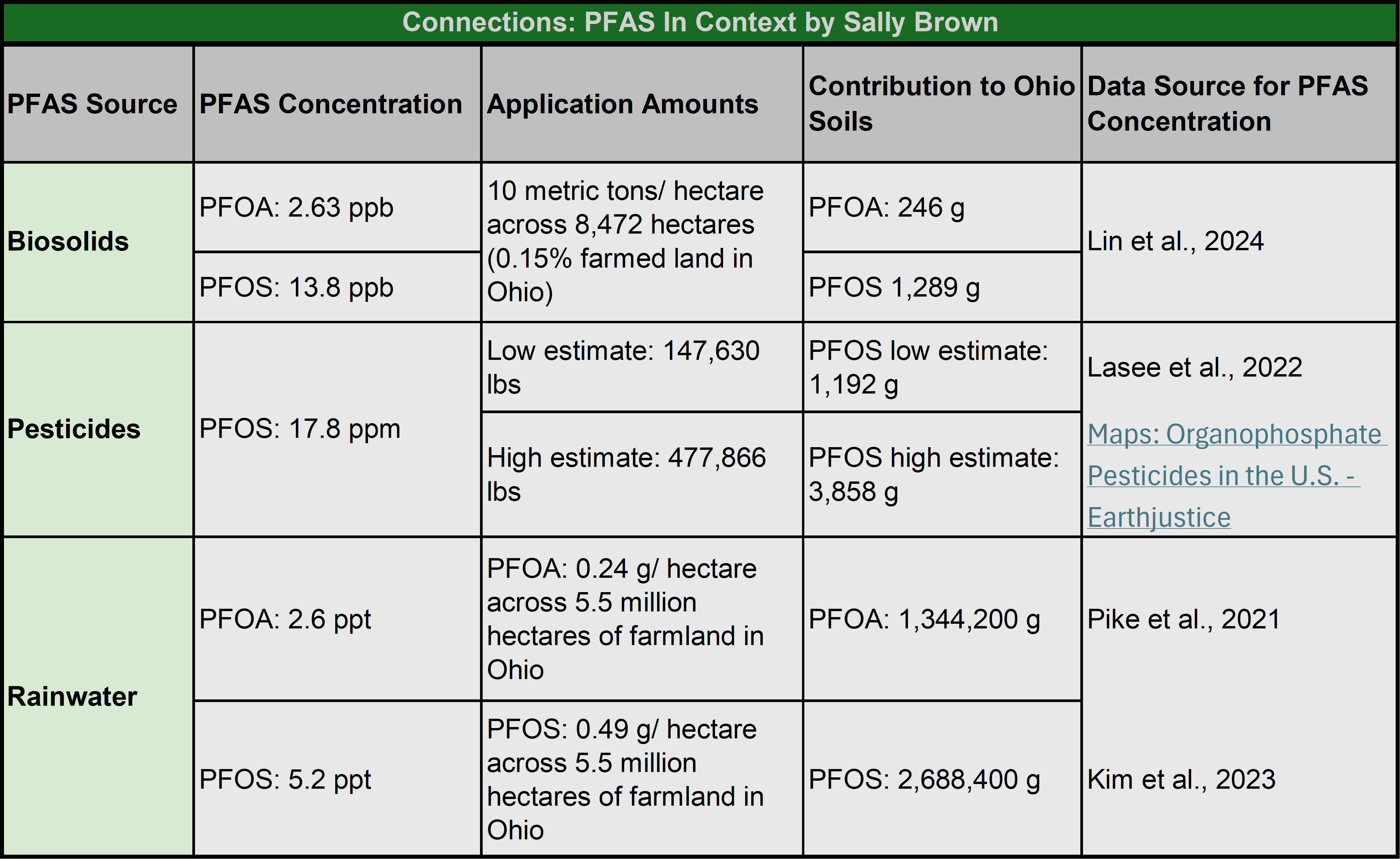

It is also important to note that there are several other pathways in which PFAS can enter farmland other than biosolids. PFAS are present in many different brands of pesticides and fertilizers, and they are also found in rainwater. One study in Wisconsin collected 91 precipitation samples from sites across the state and analyzed 34 different PFAS compounds. They found total summed PFAS concentrations ranged between 0.7-6.1 ng/L or ppt (Pfotenhauer et al., 2022). Another study took samples from both urban and rural areas in the Great Lakes region and found levels of total PFAS ranging from 2.4-4.5 ng/L or ppt (Xia et al., 2024). The levels of PFAS found in these studies are lower than Michigan’s maximum contaminant levels (MCLs) for drinking water. However, since PFAS can bioaccumulate, this is still an exposure source for agricultural land. In an article written by Dr. Sally Brown from the University of Washington, she estimated how much PFAS would be added to agricultural land from rainfall, pesticide and biosolids usage on farmland in Ohio. She calculated that by applying biosolids, 246 grams of PFOA and 1289 grams of PFOS would be added to the soil in Ohio. For pesticide applications, her low estimate calculation was 1,192 grams of PFOS added to the soil and her high estimate calculation was 3,858 grams of PFOS added to the soil. Finally, her calculation for PFAS added to soil via rainfall estimated 1,344,200 grams of PFOA and 2,688,400 grams of PFOS are added to the soil each year (table 2). This study highlights that biosolids are not the only source of PFAS being added to agricultural land, and pesticides and rainfall are potentially much larger sources of PFAS contamination in soil.

Table 2 Different sources of PFAS onto farmland in the State of Ohio calculated by Sally Brown from the University of Washington.

Other risk factors to consider before choosing to apply biosolids would be proximity to wellheads, fishable waters, or other areas that are sensitive to PFAS contamination. Fish tend to bioaccumulate high levels of PFAS if they are living in areas with high levels of contamination. Since there are no environmental scale remediation options for cleaning up large bodies of water, it is important to avoid pollutants from entering these natural resources. These factors are part of the considerations that EGLE makes prior to permitting land application of biosolids. Other landowner restrictions for biosolid applications include:

-

-

- Not harvesting crops touching the biosolid/soil mixture until 14 months post-application.

- Not harvesting food crops with the harvested portion below the surface of the land for 20 months post-application if the biosolids remained on the land surface for 4+ months before being incorporated into the soil.

- Not harvesting food crops with the harvested portion below the surface of the land for 38 months post-application if the biosolids remained on the land surface for less than 4 months before being incorporated into the soil.

- Not harvesting food, fiber or feed crops for 30 days after biosolid application.

- Not grazing animals on the land for 30 days after biosolid application.

- Not harvesting turf grown on land where biosolids have been applied with a high potential for public exposure for 1 year post-application, unless otherwise specified by a permitting authority.

- Restricting public access to land where biosolids with high potential for public exposure have been applied for 1 year post-application.

- Restricting public access to land where biosolids with low potential for public exposure have been applied for 30 days post-application.

-

If you are interested in discussing whether applying biosolids is the right decision for your farm, please reach out to Faith Cullens-Nobis (cullensf@msu.edu) and/or Katie King (kingka22@msu.edu). We are happy to help discuss potential risk factors, research about biosolids on farmland, and provide any contacts that may be able to assist you in making this decision.

Print

Print Email

Email