Drain Sedimentation Tool

For the pdf version of this bulletin, click here.

1. Overview of the Drain Sedimentation Tool

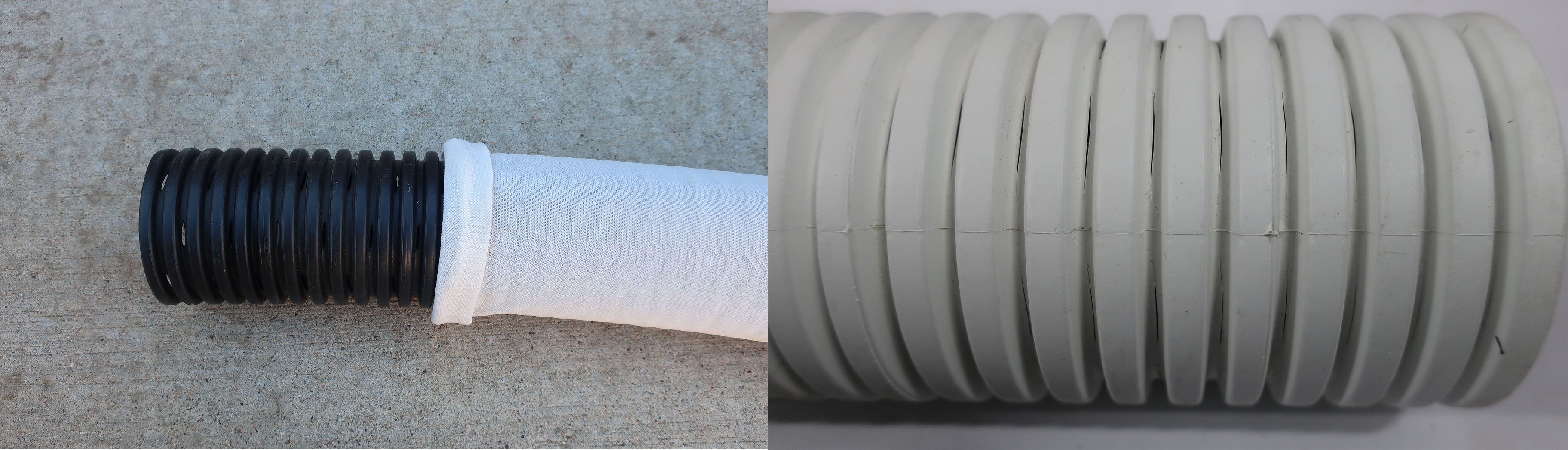

The Drain Sedimentation Tool identifies soil at risk of drain clogging (Figure 1). There are two materials that prevent sediment from entering the pipe: knitted-sock envelope and sand-slot pipe (Figure 1). Sand-slot pipes have a narrow-slot width that keep sediment out of the pipes. To use the tool, enter a few simple soil and drainage inputs. Then, the tool performs three assessments to give you a recommendation. The tool’s assessments consider 4-inch lateral drain pipes, but the recommendation is valid for mains with larger sizes. The tool helps avoid unnecessary costs of dealing with sediment-clogged pipes. The tool also helps avoid the extra cost of installing sock-wrapped pipes in situations where a sock is not needed. The tool’s recommendation should be used along with local experience.

.png?language_id=1)

2. Why is a sediment preventive measure needed?

When fine sand or silt enter subsurface drain pipes, it can remain near the entry point and build up over time, causing partial or full pipe clogging. Soil with high clay and organic matter does not cause drain sedimentation problems because soil particles stick together (cohesive soils) and do not move into the pipes. Soil with low clay and organic matter may cause a drain sedimentation problem because soil particles do not stick together (noncohesive or weakly cohesive). Example soils that can be a problem are sand, loamy sand, sandy loam, loam, silt loam, and silt. For details about sediment clogging, mitigation methods, and preventive measures, see Ghane (2025).

3. How does the tool work?

The tool goes through three assessments to determine if drain sedimentation is a problem based on the work published in Vlotman et al. (2000).

The first assessment is based on the soil clay content at the drain depth. If clay content is greater than 25%, drain sedimentation is not a problem. If clay content is less than 25%, drain sedimentation may be a problem, so the tool proceeds to assessment two.

The second assessment considers the tendency of the soil to cause siltation in the pipe. Soils with greater fine sand and silt content tend to cause siltation (Vlotman et al., 2000). If the soil does not have siltation tendency, drain sedimentation is not a problem. If siltation is a problem, drain sedimentation may be a problem, so the tool proceeds to assessment three.

The third assessment considers the resistance of the soil surrounding the pipe to the flow of water into the pipe perforations. If the soil particles stick together strongly to resist getting washed away by water, drain sedimentation is not a problem. Otherwise, you need either a sock-wrapped or sand-slot pipe to prevent drain sedimentation. The tool’s assessments consider 4-inch lateral drain pipes, but the recommendation is valid for mains with larger sizes. For details of assessment three, see the User Manual of the Drain Sedimentation Tool (www.canr.msu.edu/drainage/tools/).

4. How does this tool affect your bottom line?

The Drain Sedimentation Tool helps you make an informed design decision about the need for using either a sock-wrapped or sand-slot pipe to prevent drain sedimentation. The tool helps avoid unnecessary costs of dealing with sedimentclogged pipes. The tool also helps avoid the extra cost of installing sock-wrapped pipes in situations where a sock is not needed. Drain clogging causes under-performance of the drainage system that can reduce crop productivity.

5. Steps for using the tool

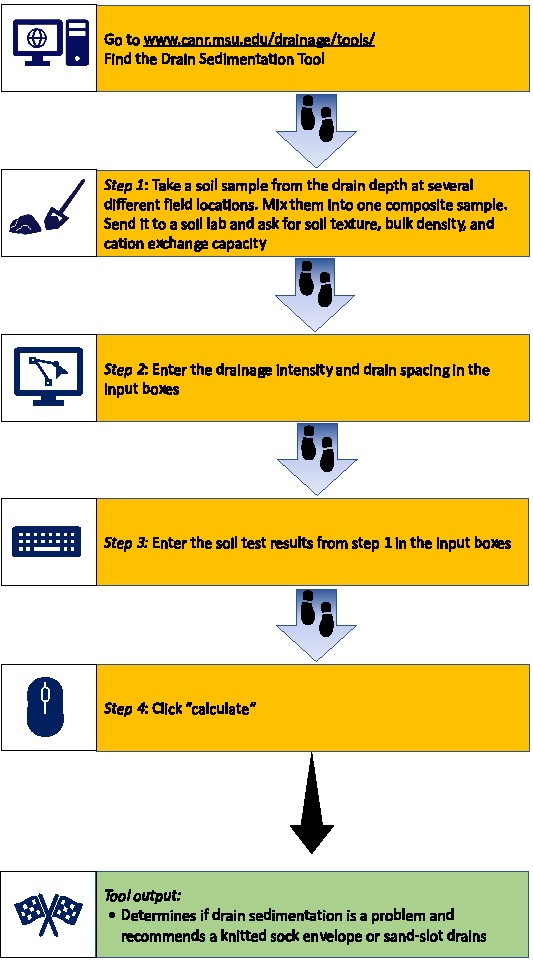

To use the tool, follow the steps in Figure 2. A detailed description of the calculation methods and inputs are in the User Manual of the Drain Sedimentation Tool (www.canr.msu.edu/drainage/ tools/).

5.1. Determining the soil inputs

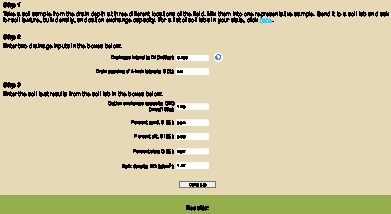

Dig a pit with an excavator, or use an auger to collect a soil sample at the drain depth from several different field locations. When auguring, an unstable hole (that is, with easily collapsing walls) is the first indication of a drain sedimentation problem. Mix the soil samples thoroughly into one composite sample. Send the composite sample to a soil lab and ask for soil texture (% sand, % silt, % clay), bulk density, and cation exchange capacity. Because the soil sample is disturbed, the soil lab will determine bulk density using the standard soil scoop method (Peck, 2015). Finally, when you receive the soil lab results, enter them in the relevant input boxes of the tool (Figure 3).

5.2. Determining the drainage inputs

The drainage intensity is the rate of water movement through the soil into the drain pipes (inches per day). To obtain the drainage intensity and drain spacing of 4-inch lateral drain pipes, follow these steps:

Step 1: Use the DrainTool to estimate the optimum drain spacing that maximizes economic return on investment (https://www.canr.msu.edu/drainage/ tools/).

Step 2: Use the drain spacing from Step 1 in the Drainage Intensity calculator to estimate the drainage intensity of the system (www.canr.msu. edu/drainage/tools/).

Acknowledgment

Dr. Ehsan Ghane contributed to the conceptualization of the tool. Josue K. Kpodo and Dr. Amirpouyan Nejadhashemi contributed to the tool development at the Decision Support and Informatics Lab (https://dsiweb.cse.msu.edu/ index.php/tools-for-agricultural/).

Expert Reviewed

The author expresses gratitude to the reviewers: Dr. Jeppe Kjaersgaard (Research Scientist, Minnesota Department of Agriculture) and Dr. Christopher H. Hay (Senior Research Scientist, Iowa Soybean Association).

References

Ghane, E. (2025). Why do subsurface drainage systems under-perform? (E3451). Michigan State University Extension. www.canr.msu. edu/drainage/

Peck, R. T. (2015). Standard soil scoop. In Recommended chemical soil test procedures for the North Central Region (North Central Regional Research Publication No. 221, Revised). Missouri Agricultural Experiment Station SB1001.

Vlotman, W. F., Willardson, L. S., & Dierickx, W. (2000). Envelope design for subsurface drains. International Institute for Land Reclamation and Improvement. Wageningen, The Netherlands.

Print

Print Email

Email