Mole Drains

For the pdf version of this bulletin, click here.

1. What are mole drains?

1. What are mole drains?

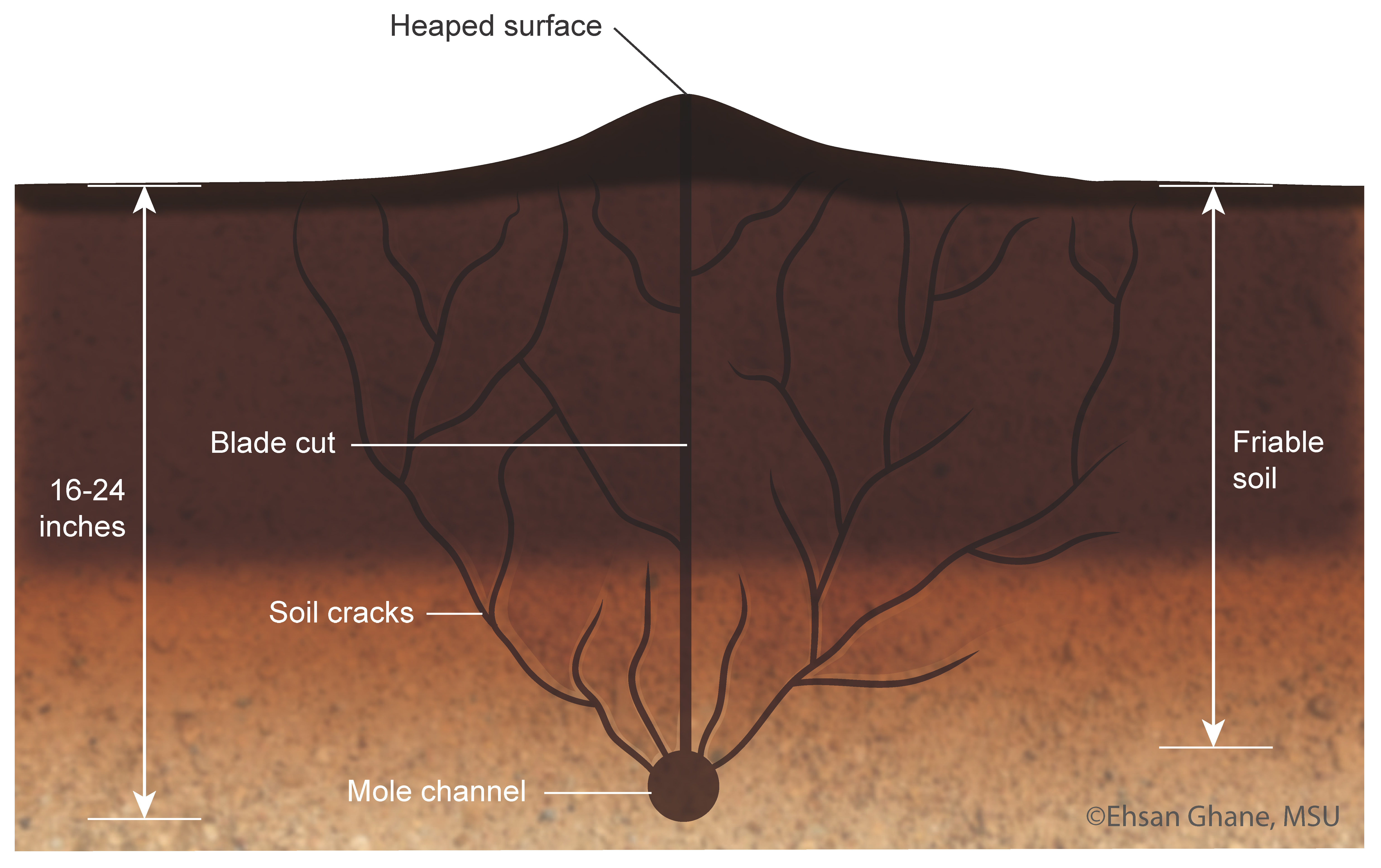

Mole drains are unlined tunnels (mole channels) in the clay subsoil formed by a mole plow (Figure 1). A mole plow is composed of a shank (leg) attached to a cylindrical torpedo foot followed by a cylindrical expander (Figure 2). The expander strengthens the channel by compacting the wall. The process of pulling the mole plow results in soil cracks. The effectiveness of mole drains depends on the amount of soil cracks that help water movement toward the mole channel.

A mole plow is similar to a subsoiler plow in that both loosen the soil and break up the plow-pan and compacted surface layer, but unlike a subsoiler, a mole plow creates an intact channel for water flow.

This bulletin covers the reasons for installing, specifications, site suitability, installation timing, combining with subsurface drainage, life expectancy, and the benefits of mole drains.

2. Why install mole drains?

2. Why install mole drains?

The following are the reasons why you may need to install mole drains:

- In soil where surface drainage is insufficient for addressing excess water problems and installing subsurface (tile) drainage is uneconomical due to low crop income, mole drains are an inexpensive means to drain excess water from the soil profile. An example location is the Upper Peninsula of Michigan.

- In heavy clay soil with low permeability, mole drains can drain excess water from the soil profile. Alternatively, mole drains can be combined with subsurface drainage to improve drainage performance in heavy clay soil (Section 6).

- When iron ochre is a temporary issue, mole drains can leach the soluble iron over the initial few years after installation. After the iron leaching has declined, install subsurface drains. For more information about iron ochre, see Ghane (2025).

- When impeded infiltration or percolation is a problem, the shank (leg) creates a blade-cut to break up the clay-pan and compacted layer (figures 2 and 3) (Ghane 2025). Also, soil cracks created from moling increase infiltration and water movement by providing a water pathway to reach the mole channel, thereby improving soil aeration (Figure 4).

3. Specification of mole drains

3. Specification of mole drains

The expander diameter is 3 to 4 inches, with the larger size generally used at deeper depths (Eggelsmann, 1978; Schwab, 1947). Mole drains are typically installed with 3-ft to 6-ft spacing (Figure 5). Since some of the channels will fail following installation, the final spacing will be wider. For example, installing at 6-ft spacing may result in a 12-ft final spacing, assuming some mole channels will fail. As a result, plan on installing narrower spacings to achieve your final wider spacing.

The depth of the mole channel is usually between 16 to 24 inches. If tractor capacity or surface traction limits mole depth in heavy clay soil, start with a shallow mole depth, no shallower than 16 inches. As the soil structure improves over the years with better infiltration and root development, increase mole depth to around 24 inches in the following installation (Vlotman et al., 2020). Generally, mole depth should be as deep as possible for the channel to be placed in the plastic subsoil. If moling is combined with subsurface (tile) drainage, care should be taken to avoid cutting the plastic drain pipes (Section 6). Deep moles last longer than shallow ones because they are less prone to damage by traffic, roots, animals, and shrinking and swelling of the soil.

Mole drains can be pulled in either direction, uphill or downhill (Hopkins 1947). The grade of the mole drains follows the slope of the land. A steeper land will have a steeper mole grade.

Mole length depends on soil type and land grade. Relatively flat fields require shorter mole lengths than steeper slopes. Generally, the maximum length of a mole drain should be about 300 ft for relatively flat fields and about 600 ft for sloping fields to ensure it lasts longer (Schwab, 1947). In some cases, longer mole lengths have been successful for several years (Hopkins, 2002). However, shorter mole lengths last longer.

If the mole channel flows into a ditch, make sure the mole outlet is far enough away from the bottom of the ditch to provide a continuous free flow (Hopkins, 2002). The mole outlet can be protected by inserting a 3- to 6-ft long piece of rigid pipe into the outlet to stabilize the channel and allow rat-guard installation (Vlotman et al., 2020) (Figure 6). The outlet must be regularly maintained, so the mole drains work as intended.

4. Suitability of mole drains

4. Suitability of mole drains

Moling is very suitable in heavy clay soil with a minimum of 45% clay content and less than 20% sand at the mole depth. Soil with a minimum of 35% clay and less than 45% sand at mole depth may be suitable. Soil with stones and clay content less than 35% are unsuitable for mole drains due to low mole channel stability.

Mole drains are very suitable on uniformly sloped landscapes with slopes ranging from 0.2% to 3.0% because the grade of the mole drains follows the landscape’s slope. If the grade is too steep (>3.0%), erosion may occur in the mole drains. If there is not enough grade in the mole channel, water stagnation will weaken the walls and lead to early collapse. Any irregularities in landscape slope will show up in the mole grade.

5. When to install mole drains

5. When to install mole drains

Best installation conditions usually occur during the summer or early fall, when the upper soil layer is as dry as possible. If the soil at mole depth has too much moisture, it leads to smearing and reduces the effectiveness of the mole drains. As a rule, the soil moisture at the mole depth should be at or just below the plastic limit.

To determine if the soil is below the plastic limit, use a soil auger or shovel to grab a handful of the soil from the mole depth. If the soil sample has gravel, separate those larger than 2 mm as much as possible. Take a small sample of the soil (about the size of a peanut) and immediately roll it between your palm and a smooth surface (glass- like surface) to create a thread. Rolling should be done under the shade to avoid the sun drying the sample. If the larger thread breaks into shorter threads, continue rolling the shorter thread. If the thread crumbles into barrel-shape pieces at a diameter greater than 1/8 inch, the soil is dry enough for moling, that is, the soil is at or below the plastic limit (Figure 7). If the thread reaches 1/8-inch diameter without crumbling into barrel- shape pieces, you have too much moisture for moling (ASTM D4318-17e1).

6. Combining mole drains with subsurface drainage

6. Combining mole drains with subsurface drainage

Mole drains can be installed as a stand-alone system, or they can be combined with subsurface drainage to improve drainage performance in heavy clay soil. The combined system can be done in one of two ways: mole channels can either drain into a ditch or into a drain trench. Both methods can address compaction issues by breaking up the plow-pan and compacted surface layer. Avoid moling under wet soil surface conditions as it could cause a compaction issue.

6.1. Mole channels empty into an open ditch

In the first method, mole channels empty into an open ditch (Figure 8). The mole channels serve two purposes: facilitating water movement toward the subsurface drain pipes and moving water toward the ditch. To avoid cutting through the existing subsurface drain pipes, keep at least a 4-inch distance between the bottom of the mole channel and the top of the drain pipes (Stuyt et al., 2005). When draining the mole channels into a ditch, the mole outlet needs to be maintained to allow continuous free flow.

6.2. Mole channels empty into a drain trench

In the second method, there is no open ditch adjacent to the field for the mole channels to empty into (Figure 9). In this case, install a collector drain trench with a gravel backfill through the lowest depressions of the field. Then, pull the mole plow through the drain trench such that the mole plow cuts through the gravel envelope without cutting through the drain pipe. Water from the mole channels empties into the gravel to reach the collector drain pipe. Then, the collector drain pipe carries water into the main pipe of the subsurface drainage system. The main pipe carries water into the county main pipe, or the main pipe carries water for some distance to reach the open ditch.

In very long fields, the mole channels may become too long to perform well if there is only one collector drain trench at the edge of the field to empty into. In this case, you may need more collector drain trenches in the field to empty into, so the mole lengths become shorter. The greater the number of drain trenches, the quicker the water removal.

Draining the mole channels into a gravel-filled drain trench has been shown to improve the performance of the drainage system in poorly permeable soil (Tuohy et al., 2018).

7. Life expectancy of mole drains

7. Life expectancy of mole drains

The lifetime of a mole drain depends on the soil’s stability and the soil moisture at mole depth during installation. However, if mole drains are properly installed in suitable soil and moisture condition, they can last beyond five years. Since the mole drains’ effectiveness decreases over time, re-run the mole drains every 3 to 4 years.

8. Benefits of mole drains

8. Benefits of mole drains

The primary benefit of mole drains is its low cost. Other benefits are improved soil physical properties and increased crop yield in heavy clay soil. When properly installed, mole drains create soil cracks that increase soil aeration, increase infiltration, and improve water movement toward the drains. The improved drainage under mole drains enhances root development and gradually improves the soil structure.

Overall, mole drains should not be considered as merely a cheap version of subsurface drainage, but as a soil-and-drainage-improvement practice.

9. Summary and recommendations

Mole drains are a low-cost practice to improve the soil physical property and drainage performance. The effectiveness of mole drains depends on the amount of soil cracks that improve water movement toward the mole channel. Moling is very suitable in heavy clay soil with a minimum of 45% clay content and less than 20% sand at the mole depth.

Plan on installing narrower spacings to achieve your final wider spacing because some of the mole channels will fail. Since the mole drains’ effectiveness decreases over time, re-run the mole drains every 3 to 4 years.

Mole drains can be combined with subsurface drainage to improve drainage performance in heavy clay soil. In one design, mole channels empty into a ditch. In the other design, mole channels empty into a gravel-filled trench with a drain pipe.

Print

Print Email

Email