Optimizing row spacing and seed placement for high yield potential in winter wheat

Optimized planting decisions such as narrow rows and adaptation of other factors can help to maximize winter wheat yields.

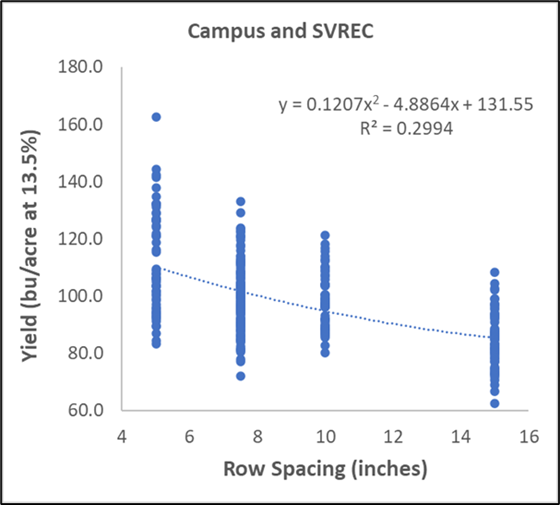

To maximize winter wheat yields, crop canopy architecture should be designed to optimize light interception and its conversion efficiency to biomass and finally grains. This can be achieved by optimizing planting decisions such as row spacing, seed placement, varietal canopy architecture and seeding rates. Previous research conducted in Michigan (Figure 1) has evaluated practices like combining the use of precision planting with narrow row spacing (5 inches) and their impact on winter wheat yield. Small-plot trials demonstrated a yield advantage ranging from 2.4% to 25.8% across four site years, shedding light on the benefits of narrow row spacing combined with the use of precision planting equipment.

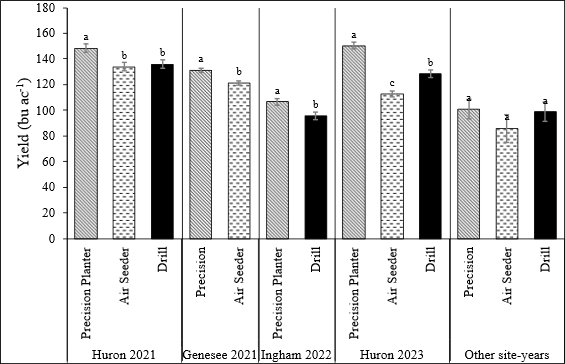

To further assess these benefits and the performance of other alternative planting methods, recently concluded research compared wheat planted at field scale using commercial Michigan farms. Results showed an 8-33% yield increase in precision planting (in 5-inch row spacing) compared to conventional drill or air seeder (ranging from 5- to 7.5-inch row spacing) at four out of eight site-years (Figure 2). Other four site-years also showed numerically higher yield using 5-inch precision planter.

Both studies have shown clear evidence that wheat is responsive to the combination of narrow rows and adopting precision planting equipment. Precision planters have become standard equipment for planting row crops such as corn and soybeans due to their ability to provide uniform depth, singulation and precise metering of the seeds. However, conventional grain drills remain common on many farms, technology that has not been changed or updated in years, alongside the same standard 7.5-inch row spacing.

As growers face increasing pressure to improve yields while managing input costs to remain profitable, planting strategies such as narrow row spacing offer a complementary approach. By optimizing both input use and row configuration, Michigan farms can enhance yield potential and overall profitability. Data from previous studies conducted a few decades ago using a seed drill also showed a pattern similar to Figure 1, leading us to hypothesize that narrow row spacing might be the driving factor here and a good starting point for growers.

Our ongoing work is evaluating how other decisions, such as varietal canopy selection, weed control, fertility, etc., might need to be changed in a narrow-row wheat production system. The overall goal is to use sound agronomic principles in setting growers up for high wheat yields that are profitable and sustainable.

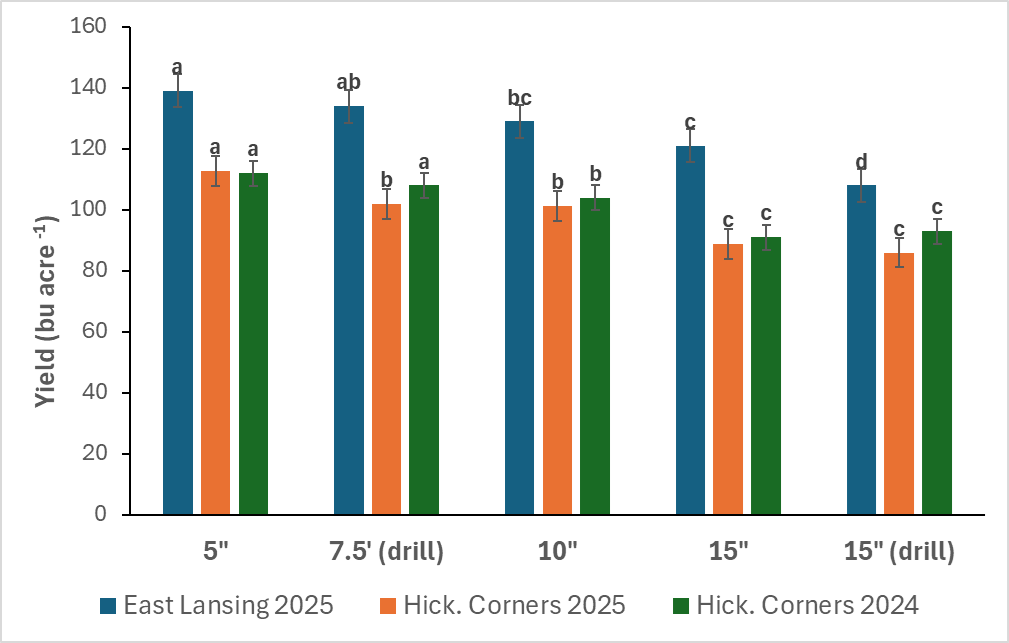

Recent results using a new custom-built precision planter have shown similar trends as shown above. Two years of research conducted at the Kellogg Biological Station in Hickory Corners, Michigan, and in East Lansing, Michigan, during 2024 and 2025 showed that 5-inch rows—achieved with a precision planter—consistently improved yield (6%, 6.6 bushels per acre) compared to the 7.5-inch rows (using seed drill) across varieties of differing canopy types (Figure 3).

Additionally, yield declined when using 10-inch (2.7%, 3.2 bushels per acre) and 15-inch (12.8%, 14.4 bushels per acre) row spacing compared to the 7.5-inch rows. We have recently purchased a narrow-row seed drill and will compare these systems to separate out the impacts of narrow rows from those of precise seed placement.

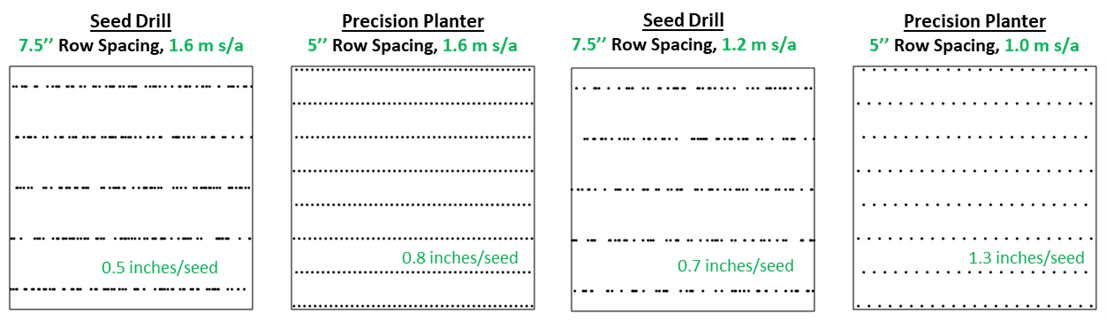

Along with the previously mentioned yield benefits of narrow rows and precision planting, this system allows us to achieve a more uniform spatial distribution around each plant (Figure 4). By reducing the spacing between rows, we can increase the spacing between plants within the row at a given seeding rate. A decrease in seeding rate for timely planted wheat can further increase spacing between plants. This extra intra-row space between plants has been associated with an increase in the number of tillers and is more likely a result of improved uniformity in seed placement and associated uniform tiller development, leading to an increase in kernels per head or kernel weight.

Overall, these results provide practical recommendations for wheat growers regarding row spacing and seeding rate recommendations for improved yield potential. Currently, the marketplace offers a few options for narrow-row grain drills that growers can use. However, these options are limited, and growers might want to think about customizing their current systems to achieve narrow rows across multiple crops. By adopting a system approach using narrow row spacing and precision planting, and the right selection of other factors, growers can make more informed decisions that can improve wheat yields.

Michigan State University Extension will continue to update results from our ongoing research in helping growers develop a systems approach to narrow-row wheat production.

Print

Print Email

Email